Learn more about Critical Minerals at www.energy.gov

Reshaping the Critical Minerals Economy

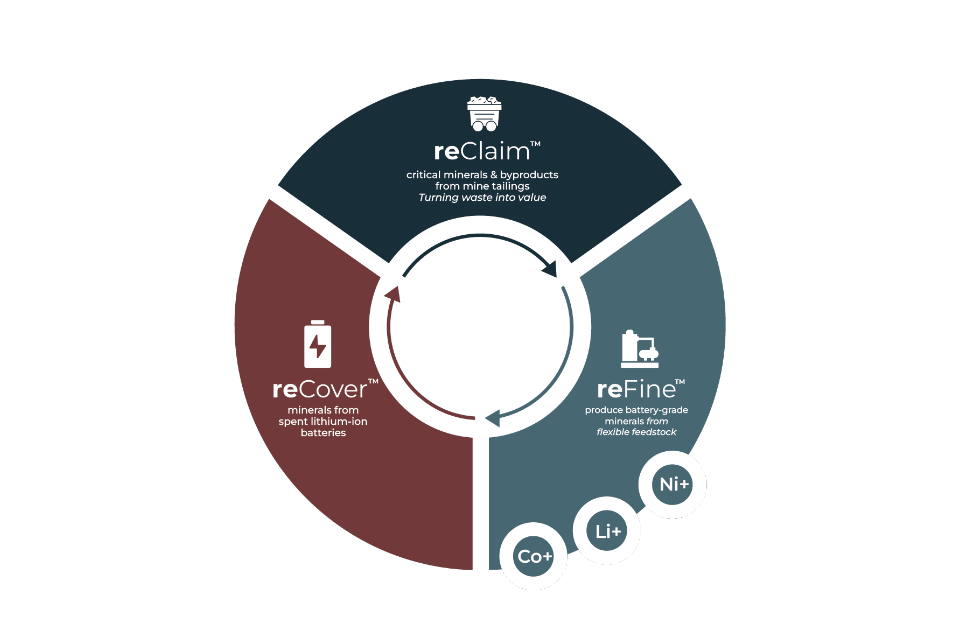

Our proprietary mineral processing solutions are robust and not reliant on any one feedstock. We have partnered with the nickel mining industry to integrate upstream extraction, midstream processing, and downstream recycling of the critical mineral supply chain. Revex is advancing circular mining solutions and benefiting communities!

Resecuring our Nation's Supply

Reclamation of mining waste and recovery from secondary and unconventional sources are priority areas for US critical mineral security.

The White House highlighted the need to increase mines domestically, expand sustainable domestic production and processing capacity, and identify new sources of supply. In particular, nickel refining was identified as a high priority.

"To establish our position as the leading producer and processor of non-fuel minerals, including rare earth minerals, which will create jobs and prosperity at home, strengthen supply chains for the United States and its allies, and reduce the global influence of malign and adversarial states."

Source: Unleashing American Energy - Executive Order January 20, 2025

Ready to Launch

Revex is acting now to help secure domestic supply chains and drive responsible production of critical minerals.

Revex has a commercial-ready solution and is preparing to start construction of a multi-plant ecosystem in the third quarter of 2025.

Reclaiming Minerals from Mine Waste & Refining Domestically

Current solutions

Costly and inefficient

Our Solutions

Lower costs and increased supply across value chain

Mine tailings (waste) management costs mining companies millions of dollars annually

Mining companies often lose significant margin selling ore concentrate to foreign smelters

Battery cell manufacturers must currently source large quantities of minerals from FTA and non-FTA countries

Revex reclaims critical minerals from mine tailings and creates new byproducts from the waste

Revex partners with mineral extractors to refine ore concentrate domestically

Revex is a sustainable domestic producer of battery-grade minerals

Current solutions

Costly and inefficient

Mine tailings (waste) management costs mining companies millions of dollars annually

Mining companies often lose significant margin selling ore concentrate to foreign smelters

Battery cell manufacturers must currently source large quantities of minerals from FTA and non-FTA countries

Our Solutions

Lower costs and increased supply across value chain

Revex reclaims critical minerals from mine tailings and creates new byproducts from the waste

Revex partners with mineral extractors to refine ore concentrate domestically

Revex is a sustainable domestic producer of battery-grade minerals

Going beyond: Recycling is only a partial solution

Recycling of Li-ion batteries and scrap, coupled with historical levels of mining, will supply only limited quantities of the forecasted critical minerals needed by battery manufacturers. There must be a significant increase in the amount of mining and processing of critical minerals in North America.

Spent Li-ion batteries are just one of the feedstocks used by Revex.

Responsible, Sustainable Design & Business Practices

Reduce Waste & Use of Virgin Material Supply

by using spent lithium-ion batteries, manufacturing scrap, and mine waste to produce battery-grade critical minerals

Strong Management Practices for a Healthy Community & Healthy World

Revex follows Responsible Care practices and has a strong commitment to sustainability intrinsic in its Code of Conduct

40% Lower Opex & Greenhouse Gas Emissions

as compared to traditional smelting methods for critical mineral processing

News & Events

REVEX TECHNOLOGIES SELECTED FOR AWARD NEGOTIATION UP TO $145 MILLION FROM THE DEPARTMENT OF ENERGY

FOR IMMEDIATE RELEASE HOUGHTON, MI (Sept 20, 2024) – Revex Technologies, a next-generation critical mineral processing company, is pleased to announce that they have been…

Read moreRevex Technologies and P&ID Partner for Battery Recycling

For Immediate Release HOUGHTON, MI – April 15, 2024 – Revex Technologies, a domestic nickel and critical minerals processing company for clean energy transition, announced today that…

Read more